2.1 Human Factors in Design and Evaluation

Many products and systems are designed without adequate consideration

of human factors. Designers tend to focus on the technology

without fully considering its use from the human point of

view. In a book every engineer should read, Norman [23] writes:

Why do we put up with the frustrations of everyday

objects, with objects thatwe can’t figure out howto use,

with those neat plastic-wrapped packages that seem

impossible to open, with doors that trap people, with

washing machines and dryers that have become too

confusing to use, with audio-stereo-television-videocassette-

recorders that claim in their advertisements

to do everything, but that make it almost impossible

to do anything?

Even when designers attempt to consider human factors, they

often complete the product design first and only then hand off the

blueprint or prototype to a human factors expert to evaluate. This

expert is then placed in the unenviable position of having to come

back with criticisms of a design that took several months to develop.

It is not hard to understand why the design team would be less than

thrilled to receive the results of a human factors analysis. Designers

clearly believe in the design, and so are often reluctant to accept human

factors recommendations. Bringing human factors analysis at

the end of the design process places everyone involved at odds with

one another. Because of the initial investment and the designer’s

resistance to change, the result is often a product that is not particularly

successful in supporting human safety, performance, and

satisfaction. Effectively integrating human factors considerations

depends on understanding the system design process.

Y Considering human factors

at the start of the design

smooths the design process.

2.1.1 System Design Processes

Systematic design processes specify a sequence of steps for product

analysis, design, and production. Even though there are many

different design processes, they generally include stages that reflect

understanding the users needs (pre-design or front-end analysis activities),

creating a product or system (prototypes, pre-production

models), evaluating how well the design meets user’s needs; all of

which is an iterative process that cycles back to understanding the

user’s needs. Product lifecycle models, are design processes that include

product implementation, utilization andmaintenance, and

dismantling or disposal. Design processes differ to the degree that

they are defined by sequential steps or by iteration, flexibility, and

adaption to uncertainty.

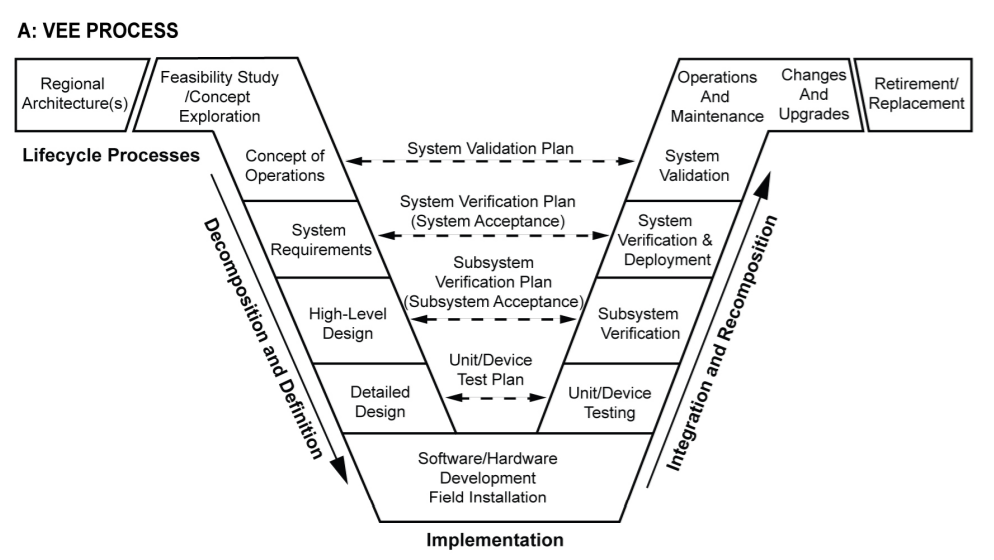

Vee process

Figure 2.1 shows three common design processes,

the first is the Vee process, which is often used in the design of

large, high-risk systems, such as the design of a new aircraft, where

sequential development is possible and verification, validation,

and documentation are critical. The Vee shape starts with a broad

system description and design requirements, which are decomposed

into detailed requirements. For the dashboard of a car, these

detailed requirementsmight include information elements, such

as speed and level of the gas tank. Design of these components

are then integrated and verified by comparing them to the original

system requirements. In the Vee process, the general specifications

are well-defined at the start and emphasis is given to documenting

a successful implementation of those specifications.

Plan-Do-Check-Act cycle.

A second design model is the Plan-

Do-Check-Act cycle (PDCA), which is commonly used to enhance

workplace efficiency and production quality [30]. The cycle begins

with the target improvement. The Plan stage describes objectives

and specifies the targeted improvement. The Plan is then implemented

in the Do stage where a product, prototype or process

is created. The Check stage involves assessing the intervention

defined by the Do stage to understand what effect it had. Act completes

the cycle by implementing the intervention or developing a

new Plan based on the outcomes. This cycle reflects the scientific

management approach of Taylor in that each plan represents a

hypothesis of how the system or product might be improved.

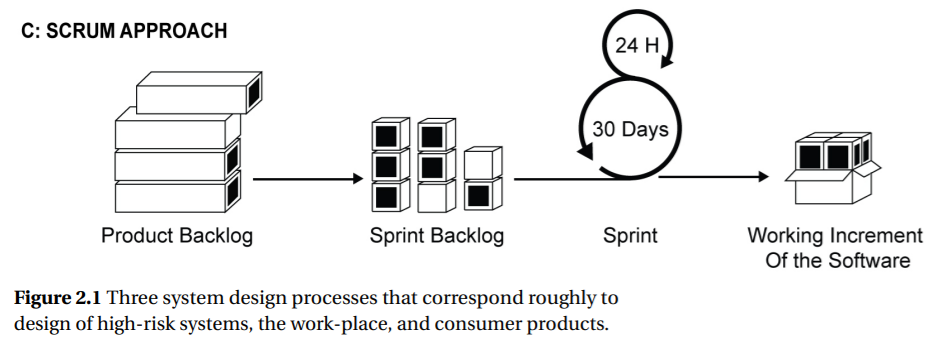

Scrum process

A third design model is the Scrum approach,

which is more typical of consumer software products, such as

smartphone and web applications, where an iterative and incremental

approach is needed to resolve uncertainty in design requirements.

The Scrum approach focuses on creating products

and using those products to discover requirements [31]. Early prototypes

reveal design opportunities that are visible only after the

technology has been implemented. Central to the Scrumapproach

is delivering systemcomponents quickly and accommodating requirements

discovered during development. “Sprints,” which are

short duration efforts, typically 24 hours to 30 days, focus effort

Figure 2.1

Three system design processes that correspond roughly to

design of high-risk systems, the work-place, and consumer products.

on quickly producing new iterations of the product. The Scrum

approach is well-suited to situations that demand high degree

of innovation, such as those where technology changes rapidly

and potential applications emerge abruptly. This flexibility is why

such techniques are sometimes termed agile design The Scrum

approach relies on close interaction between co-located workers

to develop solutions in an ad-hoc manner and therefore, the approach

tends to place less emphasis on standardized work processes,

documentation, and testing.

As noted in the introduction, cars are increasingly becoming

highly computerized consumer products. Consequently, one might

think a Scrumapproachmight be appropriate for designing a car

given the rapidly changing technology and the associated need

for innovation to stay ahead of competitors. Rapid technology

change makes it difficult to specify detailed requirements in advance.

Cars also have elements of high-risk systems that intensify

the demands to verify and validate critical safety features,making

the “Vee” model more appropriate. Such design situations demonstrate

the need for a hybrid approach that combines elements of

the Vee, Plan-Do-Check-Act, and Scrum.

Vee process focuses on methodical

implementation,

PDCA guides incremental

improvement, and Scrum

focuses on fast iteration.

Integrating Human Factors into design processes.

Effectively

integrating human factors considerations depends on matching

the methods to the demands and opportunities of the particular

design process. For example, with a short development timeline

there may be no opportunities for time consuming human factors

methods. Some of themethods described in this chapter, such as a

comprehensive task analysis, provide an accurate description, but

require weeks to months to complete. Such comprehensive methods

best fit the Vee model. Other methods that provide a less accurate

description, such as an informal observations or an Internetbased

survey, might be completed in days. These rapidmethods

best fit the Scrum model. Human factors methods trade accuracy

for speed. Understanding how to make this speed-accuracy tradeoff

is critical for inserting human factors considerations into design.

Y Select human factors methods

that fit the demands of

the design process.